Brand: ARPAC, LLC

The ARPAC Pro-Series is a semi-automated, pre-stretch film, pallet wrapper. The Pro-Series is available in a high profile model for fork lift loading and low profile model for pallet-jack loading.

With a 4,000 lb. (std.) capacity, the Pro-Series is available with a number of options (i.e. extended towers, split frames for wide loads & access ramps) that can accommodate a wide variety of pallet loads. A scale with printer can be added to the Pro-Series.

Standard Features:

- 4, 000 lb. capacity (std.)

- 74″ max. load height – high profile

- 81” max. load height – low profile

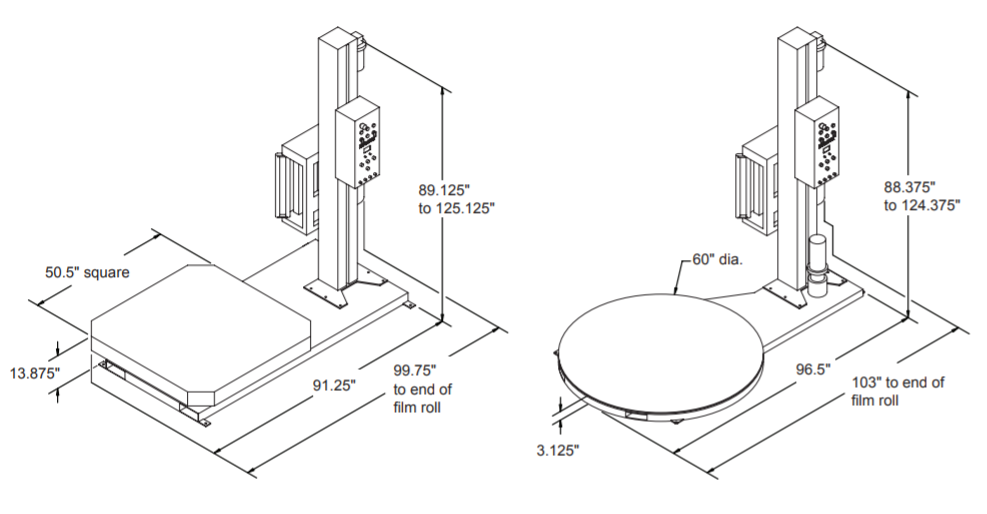

- 60″ diameter turntable – low-profile (std.)

- 50″ square turntable – high-profile (std.)

- 150 to 300% film pre-stretch EZ-Load® film pre-stretch dispenser for 20″ film rolls

- variable turntable rotation speed up to 12 RPM

- variable carriage speed up to 21 FPM

- automatic load height sensing

- automatic top film over wrap control

- electronic film tension adjustment control

- Allen-Bradley® MicroLogix™ PLC controller

- UL/CSA approved components

- powder coated steel construction

- 1/2 HP, 90 VDC motor

Options:

- Extended film tower for wrapping taller loads

- Top platen device to stabilize tall or light unstable loads

- Access ramps to assist loading of pallet

- Automatic film tear device (AFTD) tears film at end of the cycle

- Split-frame construction to increase clearance for oversized loads

- Cycle counter to count the pallets wrapped

- Extended umbilical cords for split-frame models Integrated scale and printer

Utility Requirements:

- Air: None

- Electrical: 120 VAC, 1 Ph, 60 Hz, 10 A, 1.2 kW

Approximate Dimensional Drawing: