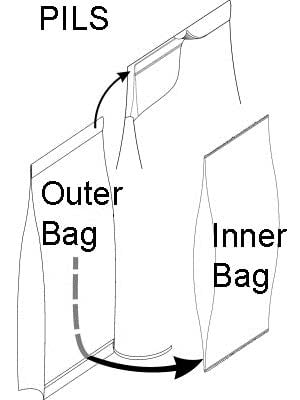

The Fischbein PILS-330 is a pinch inner liner paper bag sealer for Cap-Sac style multi-wall paper bags. Cap-Sac bags have a removable plastic bag within a paper bag. The PILS-330 can also be used to seal standard pinch inner liner paper bags.

The PILS-330™ is specifically designed for use with pinch Cap-Sac style bags that create a sift-proof, dual closure system incorporating the bag’s inner liner of heat-sealable plastic and an outer multi-wall paper bag with a standard pre-glued pinch style bag flap. For the end-user, the inner plastic liner is easily separated from its outer paper bag. Thus, contaminants acquired in transit from the factory are left on the discarded outer bag and kept from the clean-room environment.

The PILS-330 seals the bag in two stages, effectively creating a bag inside a bag. First, the PILS-330™ seals and separates the inner plastic bag from the top of the outer paper bag. Then, the PILS-330™ reactivates the bag’s pre-applied hot melt adhesive strip and automatically folds over the top of the bag forming the perfect sift-proof bag closure

The PILS-330’s unique dual-closure system is used where stringent sanitation must be maintained or where special standards (i.e. a clean-room environment) are required. Typical applications are food ingredients, pharmaceuticals or chemicals.

The PILS-330 is capable of speeds as high as 75 fpm1 and is compatible with either semi or fully automated bagging lines.

Standard Features:

- Variable drive system

- Capable of handling up to 75 feet per minute

- Open design for faster and easier maintenance

- Bag jam detector with breakaway feature eliminates downtime

- Thermal sensor prevents overheating

- Adjustable seal height reduces product changeover time

- High-efficiency heaters can cut energy requirements by up to 10%

- Extended TeflonTM folder creates a perfect durable seal

- User-friendly control panel has dual emergency stop buttons

- Easy –to-use digital key pad for efficient control and monitoring of variable speed drive system

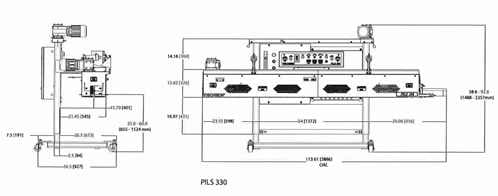

- 106″L x 37″ W

- Right-to-left bag feed

- Manual feed bag-top guide

- Bag top air scrubber removes debris

- NEMA-12 dust-tight electrics

- Accommodates bags 12″ to 20″ long, up to 56″ wide

- 18 to 110 lb filled bag weight

Options:

- Extended infeed for automated applications

- Left-to-right bag feed

- Bag coder contact front print

- Special Steel-It paint

- NEMA-4 washdown electrics

1Testing might be required to determine obtainable speeds for your application.

Utility Requirements:

- Air: 15 CFM @ 90 PSI

- Electrical: 220/440VAC, 3-Phase, 60 HZ , 25 AMPS

Startup Services:

INPAK SYSTEMS offers a startup service on your new Fischbein Model PILS-330. This includes verifying the Model PILS-330 is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Fischbein Model PILS-330. To ensure your Model PILS-330 operates at maximum efficiency, PMs can be arranged to fit your production schedule.

Mail Order Repair Services:

If you need a quick and cost effective repair of your Fischbein Model PILS-330, just box it up and ship it to one of our repair facilities. Our experienced, factory-trained, and certified technicians use genuine OEM replacement parts to ensure your Model PILS-330 is restored to its original factory operating specifications.

In-Plant Repair Services:

INPAK SYSTEMS offers in-plant repair of your Fischbein Model PILS-330. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Model PILS-330 is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

Approximate Dimensional Drawing: