The 4-Bagger is an economical, manually operated, bag filling and bag closing flatbed conveyer system from Express Scale. It is designed so that a single operator can fill, gusset, close and re-position up to 4 bags per minute. The 4-Bagger conveyor incorporates an adjustable pedestal for mounting a portable sewing head. The 4-Bagger conveyor is adjustable (i.e. belt speed, bed height, backboard position, sewing speed and sewing head position) to accommodate various applications.

Typically, the operator will position the 1st bag under a mechanical filling scale. When the 1st bag is filled it moves down the conveyor and the operator places the 2nd bag under the filler. As the 2nd bag is being filled, the operator gussets the 1st bag and guides it through the sewing head. After the 1st bag is sewn, the operator loads the bag on a pallet and returns to the filling station to load the next bag.

Standard Features:

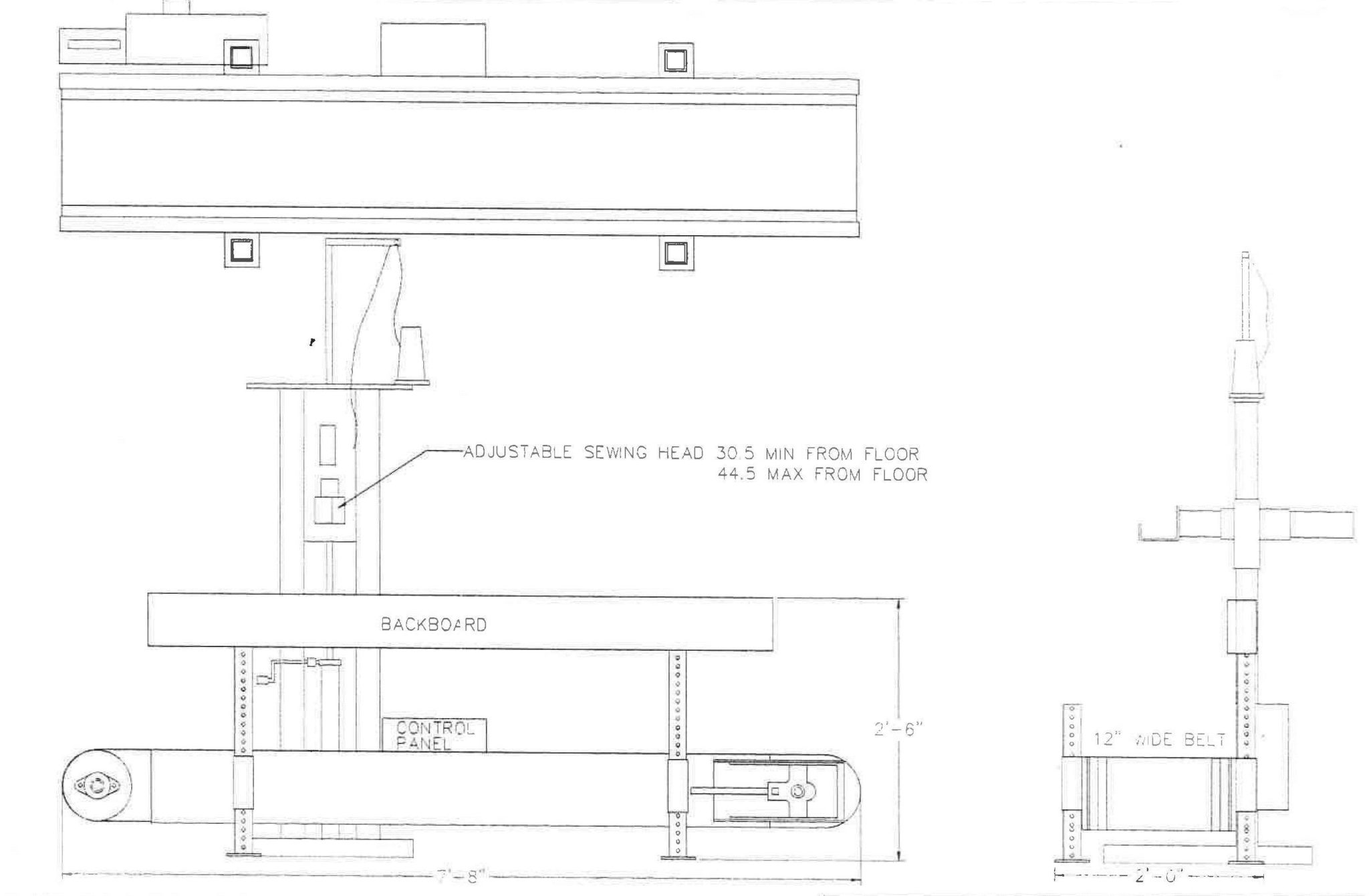

- Adjustable pedestal handles most portable type sewing heads

- 86″ long conveyor with 1/2 HP variable-speed DC motor

- 12″ wide, 3-ply, neoprene rough top belt

- Stack bags up to 4 per minute

- Adjustable height conveyor bed

- Adjustable 6″ wide metal conveyor backboard

- Sewing head easily positioned with hand crank

- Foot-pedal operator control

Options:

- Flexible design accommodates various combinations of sewing head, scale, bin capacity, and conveyor characteristics to meet your specific needs. Call 608-221-8180 for details or email [email protected]

1Testing might be required to determine obtainable speeds for your application.

Utility Requirements:

- Air: None

- Electrical: Choice of 120VAC, Single-Phase, 60HZ or 220VAC, Single-Phase, 60HZ

Startup Services:

INPAK SYSTEMS offers a startup service on your new Model 4-Bagger. This includes verifying the Model 4-Bagger is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Model 4-Bagger. To ensure your Model 4-Bagger operates at maximum efficiency, PMs can be arranged to fit your production schedule.

Mail Order Repair Services:

If you need a quick and cost effective repair of your Model 4-Bagger, just box it up and ship it to one of our repair facilities. Our experienced, manufacturer-trained, and certified technicians use genuine OEM replacement parts to ensure your Model 4-Bagger is restored to its original factory operating specifications.

In-Plant Repair Services:

INPAK SYSTEMS offers in-plant repair of your Model 4-Bagger. Our experienced, manufacturer-trained, and certified technicians use genuine OEM parts to ensure your Model 4-Bagger is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

Approximate Dimensional Drawing: