Fully electronic and digitally controlled, the JM-FF-ED Electronic Gross Weigher* simultaneously weighs and fills open-mouth bags weighing between 20 and 110 pounds at speeds up to eight bags per minute, depending on your operational parameters. The dual position gravity gate allows for bulk or dribble feed and provides accuracies of +/- 4 ounces, based on product flow and the consistency of bulk density. Wraparound bag clamps are sized to your particular bag requirements. Air-operated center-grip bag spout facilitates dust control with flexible connection to main housing. GSE 465 controller with IP-66 stainless steel enclosure is rated NEMA 4X and features Final Target Weight, Slow Fill, Free Fall, Fill Delay, Clamp Delay, and Pound/Kilogram controls.

*Gross weigh = product is weighed as it is put in the container

INPAK SYSTEMS stocks many Model JM parts. A Model JM parts diagram and a list of common Model JM replaceable parts is available.

STANDARD FEATURES:

- Obtainable accuracies of +/- 4 ounces

- Speeds up to 8 bags per minute for bags;weighing between 20-110 lbs

- Dual position gravity gate allows for bulk or dribble feed

- Adjustable proximity switch for weight cutoff

- Adjustable flow control

- Wraparound bag clamps sized to suit your requirements

- Flexible connection between spout and the main housing to control dust

- Trigger trip-screw for easy weight adjustment

- 2″ dust pickup port on left rear to connect to your vacuum system

- Adjustable timers to suit your needs

- Mild steel construction

- GSE 465 controller with IP-66 stainless steel enclosure is rated NEMA

OPTIONS:

- Stainless steel construction

- Belt feeder for free-flowing products

UTILITIES

- Air:6CFM@90PSI

- Electrical: 120VAC, Single Phase, 60HZ

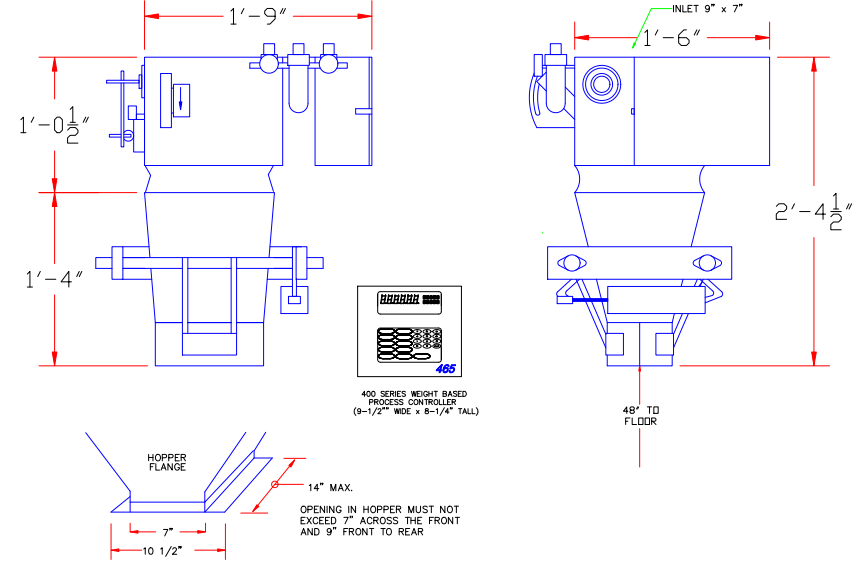

APPROXIMATE DIMENSIONAL DRAWINGS

STARTUP SERVICES

INPAK SYSTEMS offers a startup service on your new ESP Model JM-FF-ED. This includes verifying the Model JM-FF-ED is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

PREVENTIVE MAINTENANCE SERVICES

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your ESP Model JM-FF-ED. To ensure your Model JM-FF-ED operates at maximum efficiency, PMs can be arranged to fit your production schedule.

IN-PLANT REPAIR SERVICES

INPAK SYSTEMS offers in-plant repair of your ESP Model JM-FF-ED. Our experienced, manufacturer-trained, and certified technicians use genuine OEM parts to ensure your Model JM-FF-ED is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.