Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

In this blog post, we’re reviewing a Filling option in the form of the Express Scale ESP GB-32 Bagging Scale.

Express Scale ESP GB-32 Bagging Gross Weigher

The Express Scale ESP GB-32 Bagging Gross Weigher is a reliable and straightforward mechanical bagging scale designed for efficiently filling open-mouth bags with free-flowing granular products like corn, soybeans, pellets, and seeds. It’s a manual operator workhorse, perfect for medium-volume production.

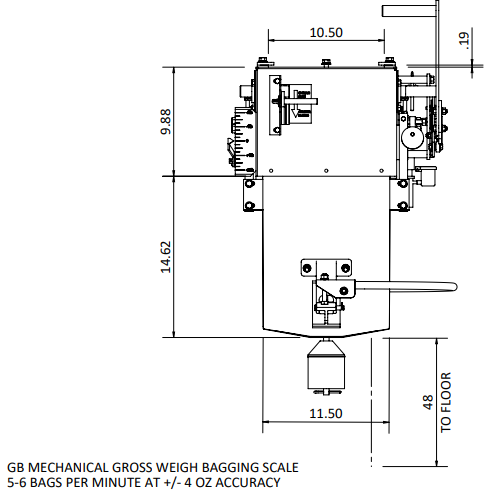

The GB-32 can simultaneously weigh and fill up to 7 open-mouth bags/minute. The GB-32 is designed to fill 50-115 lb. open-mouth bags with circumferences larger than 32″. Fully mechanical, requiring no external power, the GB-32 is ideal for most free-flowing, non-dusty products.

Photo of ESP GB-32

Key Features of the ESP GB-32:

- High efficiency: Can fill up to 7 bags per minute with accuracies of +/- 4 oz per 50 lbs

- Versatility: Handles bags with circumferences larger than 32″ and capacities ranging from 50 to 115 lbs

- Durability: Fully mechanical construction requires no external power and makes it ideal for harsh environments

- Ease of use: Simple operation with a tare weight function for zeroing out empty bags, balance indicator for accurate filling, and trigger trip screw for easy weight adjustment

- Portability: Lightweight and compact design makes it easy to move around

- High accuracy: ±4 oz (100 gram) accuracy on all free-flowing materials

- Fast filling speeds: Up to 4-5 bags per minute

- Wide range of bag sizes: Accommodates bags from 10 to 110 lbs

- Flexible spout sizes: A variety of spout sizes are available to accommodate different bag dimensions

- Durable construction: Available in mild 10 gauge steel or with stainless steel product contact surfaces

- Easy operation: Simple and intuitive controls

- Low maintenance: Requires minimal maintenance

- Variety of options: Available with Flex-Belt and Auger feeders for non-free flowing materials, and in all-stainless steel construction for corrosive or food-grade products

Benefits of the ESP GB-32:

- Increased productivity: Fills bags much faster than manual methods, saving time and labor costs

- Improved accuracy: Reduces overfilling and underfilling of bags, ensuring consistent product weight and reducing waste

- Lower operating costs: No electricity required, making it a cost-effective solution for many businesses

- Easy maintenance: Simple design with readily available replacement parts makes it easy to keep the scale up and running

- Versatile: Can be used with a wide variety of products and bag sizes

Quick Comparison of GB-32 and JM-FF-ED from Express Scale models

Both the GB-32 and JM-FF-ED from Express Scale are gross weigh baggers, meaning they weigh the bag and contents together. However, they differ in their level of automation and operation. Here’s a comparison to help you choose the best one for your needs:

Operation:

- GB-32: Manual. The operator pulls a lever to open the gate and fill the bag. Weight is controlled by adjusting the filling time

- JM-FF-ED: Electronic. The scale automatically weighs the product and stops filling when the desired weight is reached

Speed:

- GB-32: 4-5 bags per minute

- JM-FF-ED: Up to 8 bags per minute, depending on bag weight and product flow

Accuracy:

- GB-32: +/- 4 ounces

- JM-FF-ED: +/- 4 ounces, based on product flow and consistency

Other features:

- GB-32: Simple and durable, requires minimal maintenance. Can be customized with different spout sizes and shapes

- JM-FF-ED: More features like dual position gravity gate for bulk or dribble feed, adjustable flow control, dust control connection, and programmable timers

Cost:

- GB-32: Less expensive

- JM-FF-ED: More expensive due to its electronic components and features

Summary:

- Choose the GB-32 if:

- You need a simple and affordable bagger

- You have low production volume

- You don’t mind manual operation

- Choose the JM-FF-ED if:

- You need higher speed and accuracy

- You want automation and more control over the filling process

- You have a higher budget

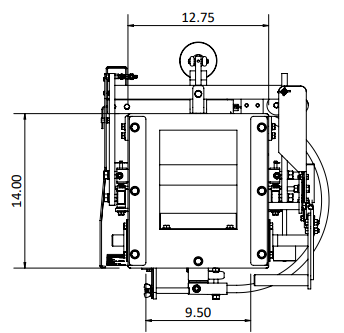

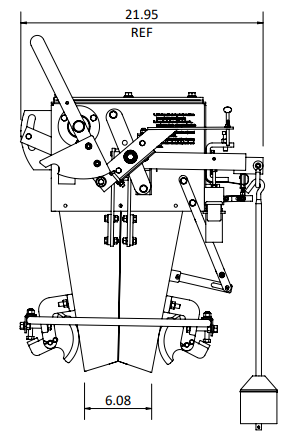

Dimensional drawings of ESP GB-32 Gross Weigher

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected]. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and Parts & Services are just a few steps away.

Make a positive impact and contact Inpak Systems.