The Chantland Model 4234 Belt-Weigh is a gross-weigh, belt-fed bagging scale designed to fill 20 to 110 lb. open mouth bags, pails, boxes and drums with dry pelleted, granular, powdered, flaked or irregular shaped products such as soil mulches, refractory cements, wood chips, chemical flakes, and similar products that do not gravity feed well.

The Model 4234 is especially suited to difficult or non-free-flowing products and can achieve rates up to (six) 50 pound bpm with accuracies as high as +/- 0.25% for load cell weighing or +/- 0.50% for scale beam weighing, based on product flow and the consistency of bulk density.1

The Model 4234’s inlet to the filler attaches to the discharge of the customer product hopper. When signaled to start, the feeder belt meters product into the bag. As the weight in the bag equals the preset weight, the belt feeder stops and the fill is complete. The operator can release the bag and installing another empty bag restarts the cycle. Bulk-Dribble feed can be accomplished by optional variable speed drive on the feeder belt on Load Cell units.

STANDARD FEATURES:

- Fill Rates: up to (5) 50 lb. bags per minute.

- Fill Weights: 20 lbs. to 110 lbs.

- Weight Accuracy: +/- 4 to 6 ounces of target weight (+/- 2 to 4 ounces with load cells).

- Scale beam gross weigh.

- Belt feeder.

- Automatic start with no-bag/no-dump interlock.

- Pneumatic bag clamps.

- Adjustable flow control gate.

- 6.1/2” x 11” oval spout.

- NEMA 12 electrical system.

- Mild steel construction.

OPTIONS:

- Net weigh design.

- Load cell weighing with digital controller.

- Stainless steel contact surfaces.

- Food grade construction.

- Anti corrosive package.

- Two stage variable speed for bulk/dribble feed.

- Dust collection hood with manifold.

- Special paint finishes.

- Special electrical packages.

- Supply and transition hoppers.

- Closing conveyors. (Model 4201, 4214 and V-series)

- Sewing head or heat sealer.

1Testing might be required to determine obtainable speeds and accuracy for your application.

UTILITY REQUIREMENTS

- Air: 1.5 CFM @ 80 PSI maximum

- Electrical: 120VAC, Single Phase, 60HZ

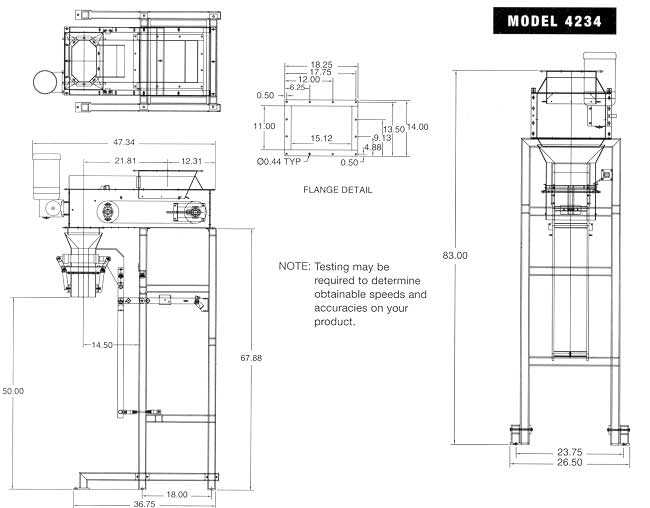

APPROXIMATE DIMENSIONAL DRAWING