The Choice Bagging Equipment (CBE) 938 is an automated, horizontal, impeller driven electronic scale used to weigh and fill fine powders of low to mid-ranged bulk density directly into 20 lb. -110 lb. (9-50KG) valve type bags at a rates up to 12 bags/minute. Examples of bulk low density powders Include: cement, vermiculite, polystyrene, kaolin, clay, silica, graphite, carbon black, organic pigments, oats, rice hull ash. The 900 Series is NOT recommended for granular products, materials of large particle size, fibrous materials or any kind of non-free flowing materials.

The 938 horizontal impeller packer has a totally enclosed product flow path from the supply hopper all the way into the bag. It can also be equipped with our 112-100 dust collection manifold which can be ducted to your plants dust suppression system. Together with our optional Tube Clean-out, Expanding Bag Seal Assembly and a filling spout arrangement, the 938 is the cleanest filling horizontal style impeller available on the market.

Operation:

The 938 impeller packer has a specially designed horizontal 4-blade feed impeller powered by a vertical drive shaft. Product flows by gravity from the supply hopper into the product feed inlet at the top of the machine. When a fill cycle is initiated, the horizontal impeller creates a positive draw on the product moving it through the feeder and into the bag.

STANDARD FEATURES:

- Weight range: 20-110 lb. (9-50KG) valve bags

- Fill rate: up to 12 bags/minute

- Typical accuracy: +/- 0.5-1% of target weight

- Mild steel contacting surfaces

- Mechanical scale weighing

- Scale isolator assembly

- Tubular steel framework

- 4-blade impeller

- 7.5 HP belt drive assembly

- Manual start/stop push buttons

- Air operated bag clamp & pinch tube material cutoff

- Adjustable bag rest

- 1.5” -2.75” single wall fill spout

OPTIONS:

- Bulk & dribble (two-stage) cutoff

- Digital load cell weighing

- Automatic bag discharger

- Digitally variable fast/slow speed impeller

- Tube clean-out assembly (only available w/digital load cell)

- Dust collection pickup manifold

- Auto start assembly

- Tapered cone dust seal

- Timed bag seal assembly

- 304 SS contacting surfaces

- Hard faced impeller

UTILITIES:

- Air: 80 PSI @ 1 CFM per bag fill cycle (400 CFM minimum for dust collection)

- Electrical – 220/440 Volt / 3 Ph / 60 Cycle (step down transformer for 110V control voltage included)

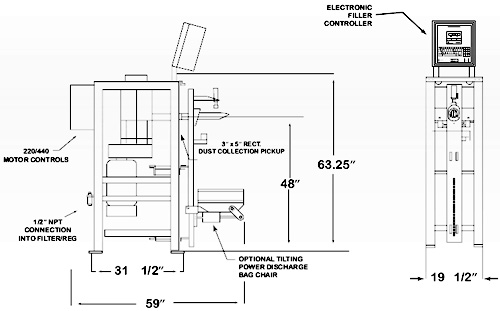

APPROXIMATE DIMENSIONAL DRAWING: