The PBC 6000 is a pinch bag sealer that uses hot air to activate a pre-glued flap on multi-walled paper bags that is rolled over and pressed closed.

The PBC 6000 is used on semi-automated or fully automated bag closing lines to seal 8-110 lb. flat or gusseted paper bags. Able to handle bags 12”-20” long and up to 56” wide makes the PBC 6000 is perfect for human and pet foods, bakery mixes, dry chemicals, fertilizers, pesticides, and similar products.

Inpak Systems stocks many replaceable parts. A PBC 6000 parts diagram and a list of common replaceable PBC 6000 parts is available.

Standard Features:

- Quality engineered to provide a sift-resistant closure

- Speeds up to 85 feet-per-minute1

- Accommodates a full range of pre-glued, multi-wall, pinch-style paper bags

- Advanced features ensure bag closures of unmatched reliability

- High-speed, maintenance-free, direct-drive system is more efficient and reliable

- Hot-air distribution manifold uses dual-finned elements for improved heat delivery to the bag

- Non-stick folder blade closes bags gradually

- Right to left bag feed

- Mobile height-adjustable frame allows for safe & fast maintenance

- Safe and user-friendly low-voltage control panel

- 8″ infeed

- Thermal overload protection

- 73″L x 35″ W (1854 mm L x 889 cm W)

- 710 lbs (322 kg) net weight

- Accommodates bags 12″ to 20″ long, up to 56″ wide

- 18 lbs to 110 lbs filled bag weight

- Patented breakaway feature for easy maintenance

- Digital temperature control and readout

- Over-temperature sensor with auto shutdown

- Bag jam detector and safety on/off switch

- Digital control and readouts

- Variable AC-VFD speed control

- 6 month factory warranty

Options:

- 17″ extended infeed for automated applications

- Reverse fold-rear direction

- Left to right bag feed

- Bag coder contact front print

- Motorized height adjustment lift

- Special Steel-It paint

- NEMA-4 washdown electrics

1Testing might be required to determine obtainable speeds for your application.

Utility Requirements:

- Air: 10 to 15 CFM @ 90 PSI

- Electrical: 220/440 VAC, 3-Phase, 60 HZ

Startup Services:

INPAK SYSTEMS offers a startup service on your new Fischbein Model PBC 6000. This includes verifying the Model PBC 6000 is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Fischbein Model PBC 6000. To ensure your Model PBC 6000 operates at maximum efficiency, PMs can be arranged to fit your production schedule.

Mail Order Repair Services:

If you need a quick and cost effective repair of your Fischbein Model PBC 6000, just box it up and ship it to one of our repair facilities. Our experienced, factory-trained, and certified technicians use genuine OEM replacement parts to ensure your Model PBC 6000 is restored to its original factory operating specifications.

In-Plant Repair Services:

INPAK SYSTEMS offers in-plant repair of your Fischbein Model PBC 6000. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Model PBC 6000 is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

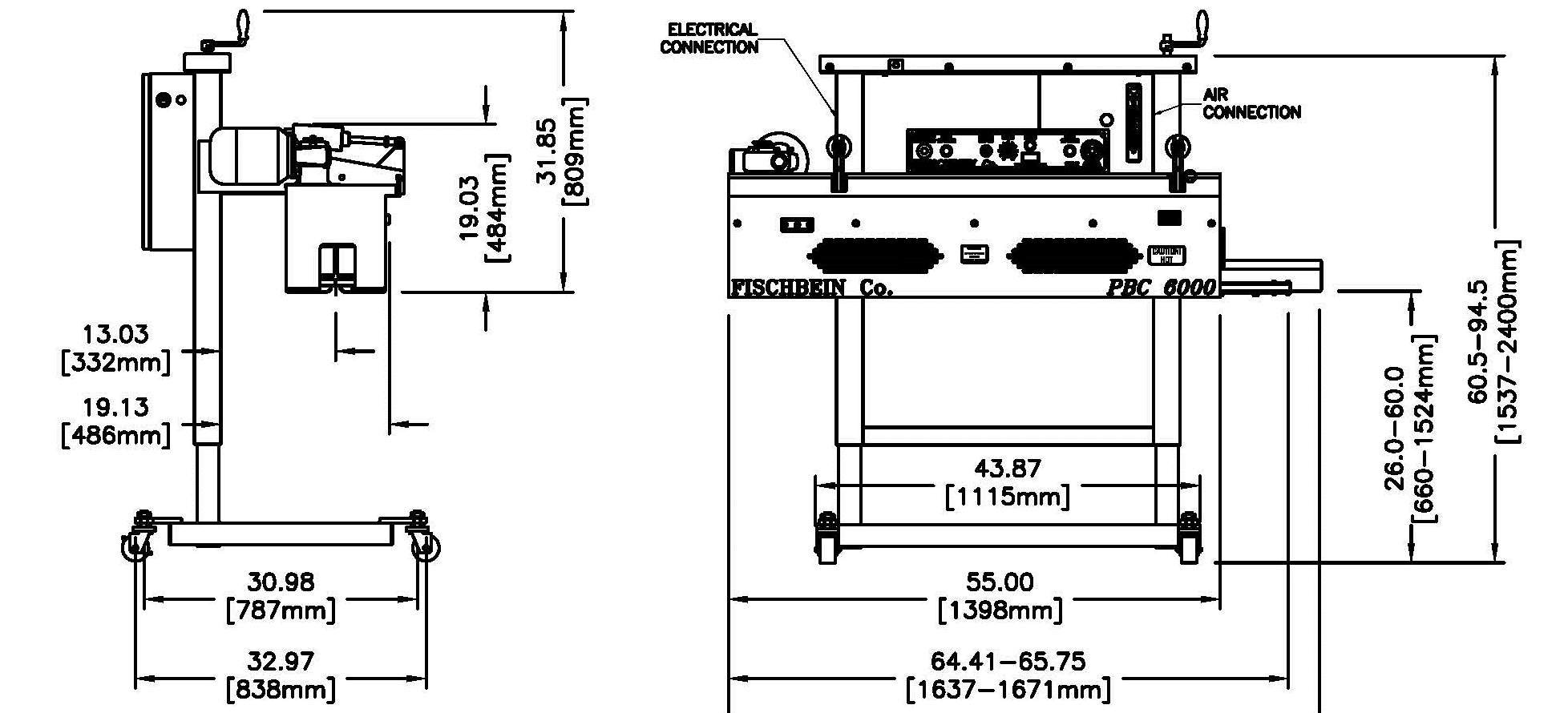

Approximate Dimensional Drawing: