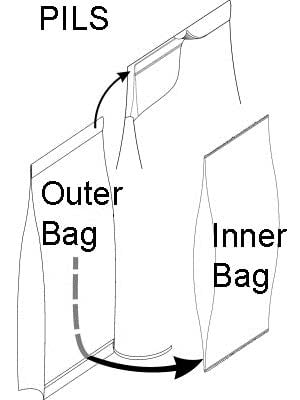

The Fischbein PILS-300 is a pinch inner-liner paper bag sealer for multi-wall paper bags. The PILS-300 is especially designed to close pinch-style bags that additionally incorporate a heat-sealable polyethylene or foil liner.

Bags are typically stepped-end, multi-wall paper bags with a pre-applied hot melt adhesive strip. The PILS-300 makes two separate and consecutive closures in a single pass. First, the PILS-300 seals the inside PE liner. Then it activates the bag’s pre-applied hot-melt adhesive strip and automatically folds over the top of the bag forming the perfect sift-proof bag closure.

The sift-proof closure makes this bag style perfect for use with certain food products, food additives, dry chemicals, fertilizers, pesticides and pet food products. The PILS-300 is capable of speeds as high as 75 fpm1 and is compatible with either semi or fully automated bagging systems.

INPAK SYSTEMS stocks many replaceable parts. A PILS 300 diagram and a list of common replaceable PILS 300 parts is available.

Standard Features:

- Variable speed drive system

- Capable of handling up to 75 feet per minute

- Open design for faster and easier maintenance

- Bag jam detector with breakaway feature eliminates downtime

- Manual feed bag top guide

- Bag top air scrubber removed debris

- Thermal sensor prevents overheating

- Right to left bag feed

- Adjustable seal height reduces product changeover time

- High-efficiency heaters can cut energy requirements by up to 10%

- Extended TeflonTM folder creates a perfect durable seal

- User-friendly control panel has dual emergency stop buttons

- Easy –to-use digital key pad for efficient control and monitoring of variable speed drive system

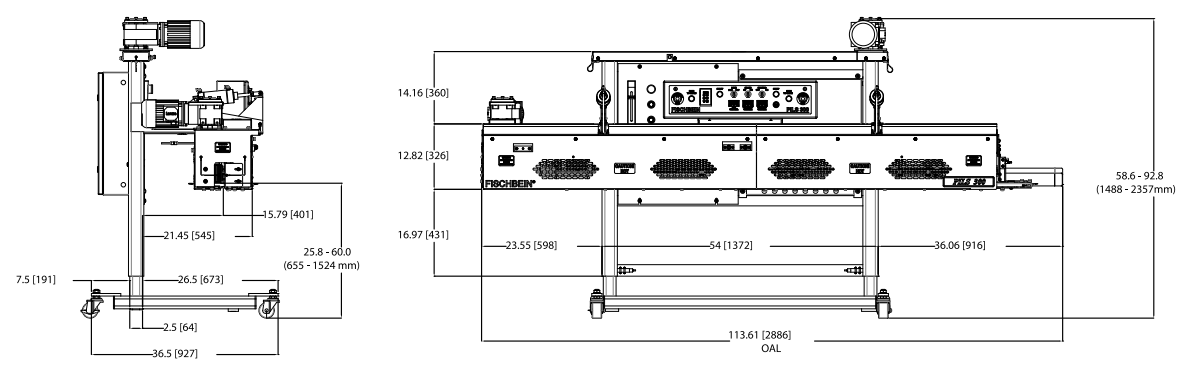

- 106″L x 37″W

- Manual feed bag-top guide

- Accommodates bags 12″ to 20″ long, up to 56″ wide

- 18 lbs to 110 lbs filled bag weight

- NEMA-12 dust-tight electrics

Options:

- Extended infeed for automated applications

- Reverse fold-rear direction

- Left to right bag feed

- Bag coder contact front print

- Motorized height adjustment lift

- Special Steel-It paint

- NEMA-4 washdown electrics

1Testing might be required to determine obtainable speeds for your application.

Utility Requirements:

- Air: 15 CFM @ 90 PSI

- Electrical: 220/440 VAC, 3-Phase, 60 HZ , 25 AMPS

Startup Services:

INPAK SYSTEMS offers a startup service on your new Fischbein Model PILS-300. This includes verifying the Model PILS-300 is operating properly to factory specifications. The startup service includes operation verification, operator training and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Fischbein Model PILS-300. To ensure your Model PILS-300 operates at maximum efficiency, PMs can be arranged to fit your production schedule.

Mail Order Repair Services:

If you need a quick and cost effective repair of your Fischbein Model PILS-300, just box it up and ship it to one of our repair facilities. Our experienced, factory-trained, and certified technicians use genuine OEM replacement parts to ensure your Model PILS-300 is restored to its original factory operating specifications.

In-Plant Repair Services:

INPAK SYSTEMS offers in-plant repair of your Fischbein Model PILS-300. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Model PILS-300 is restored to original factory operating specifications. Dispatched from either our WI or OH locations ensure a quick response throughout the Midwest.

Dimensional drawings of Fischbein PILS-300 (inches [mm])