Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

In this blog post, we’re reviewing a Closing option in the form of the Fischbein PILS-330 Pinch Inner-Liner Sealer (PILS) for Cap-Sac style multi-wall paper bags.

Fischbein PILS-330 Pinch Inner-Liner Sealer for Paper Bags

The Fischbein PILS-330 is a pinch inner-liner paper bag sealer designed for Cap-Sac style multi-wall paper bags. Cap-Sac bags are used when protection from moisture, air, and contaminants is needed.

The PILS-330 features a continuous sealing process that sequentially seals and perforates the bag’s inner liner, creating a bag within a bag, and then folds and seals the top of the pre-glued pinch bag.

The machine makes two separate and consecutive closures in a single pass. Operating at speeds up to 75 linear feet per minute, the PILS-330 is safe, easy to use, and can be easily integrated into semi- or fully automated bagging applications.

The PILS-330 seals the Cap-Sac bag in two stages, effectively creating a bag inside a bag. First, the PILS-330™ seals and separates the inner plastic bag from the top of the outer paper bag. Then, the PILS-330™ reactivates the bag’s pre-applied hot melt adhesive strip and automatically folds over the top of the bag forming the perfect sift-proof bag closure.

The patented breakaway design eliminates costly downtime caused by bag jams while allowing easy cleaning and service of the hot air manifold and bag folder. It’s also engineered with a high-speed, maintenance-free, direct drive system that maximizes production.

The PILS-330’s sift-proof closure makes this Cap-Sac bag style perfect for use with certain food products, food additives, dry chemicals, fertilizers, pesticides, and pet food products. It’s used where stringent sanitation must be maintained or where special standards (i.e. a clean-room environment) are required.

Photo of Fischbein PILS-330

Key features of the Fischbein PILS-330:

- The PILS-330 creates a “bag within a bag” by sealing and perforating the inner plastic liner and then folding and sealing the top of the outer paper bag. This provides a sift-proof closure that is ideal for applications where stringent sanitation or contamination control is required.

- Seals bags at speeds of up to 75 linear feet per minute, making it a productive choice for high-volume packaging operations

- The PILS-330 is versatile and can be used with both pinch top inner liner (Cap Sac) style bags and standard pinch inner liner paper bags

- Has a user-friendly control panel with a digital temperature display, variable speed control, and dual emergency stop buttons

- Safe and reliable as it features a patented breakaway design that prevents bag jams and allows for easy cleaning and service. It also has an over-temperature sensor that automatically shuts down the machine to prevent damage.

- The PILS-330 is durable and made of heavy-duty stainless steel and is built to last in demanding industrial environments

- Pre-heating station for pre-applied glue

- Single fold-over station

- Has a final bag heat-sealing and cooling area

- Hand crank height adjustable frame with casters for easy movement

- Digital temperature display

- Keypad for variable speed control

- Machine start/stop button + Dual emergency e-stop buttons

Benefits of using the Fischbein PILS-330:

- Dual closure system: The PILS-330 creates a sift-proof closure by sealing and perforating the inner plastic liner and then folding and sealing the top of the outer paper bag. This double layer of protection helps to prevent leaks, spills, and contamination, ensuring your products arrive safely to your customers.

- Extended shelf life of the in-bag product: The airtight seal created by the PILS-330 helps to preserve the freshness and quality of your products by protecting them from moisture, oxygen, and other environmental factors. This can extend the shelf life of your products and reduce spoilage.

- High-speed operation: The PILS-330 can seal bags at speeds of up to 75 linear feet per minute, significantly improving your packaging throughput. This can lead to increased production speeds and reduced labor costs.

- Reduced downtime: The PILS-330’s patented breakaway design eliminates costly downtime caused by bag jams. This feature allows for quick and easy clearing of any obstructions, keeping your packaging line running smoothly.

- Easy to use and maintain: The PILS-330 has a user-friendly control panel and is designed for easy cleaning and maintenance. This makes it a good choice for businesses of all sizes, regardless of their experience level with packaging equipment.

- Versatility: The PILS-330 can be used with both pinch top inner liner (Cap Sac) style bags and standard pinch inner liner paper bags, making it a versatile solution for a variety of packaging needs.

- Durability: The PILS-330 is constructed from heavy-duty stainless steel and is built to last in demanding industrial environments. This makes it a reliable investment that will provide years of trouble-free operation.

- Improved brand image: Using a high-quality bag sealing solution like the PILS-330 can help to improve your brand image by demonstrating your commitment to quality and product protection.

- Increased productivity: The PILS-330 can seal up to 75 linear feet of bags per minute, which can help to improve productivity and reduce labor costs.

- Reduced downtime: The PILS-330 is designed to be easy to use and maintain, which can help to reduce downtime and keep your production line running smoothly.

- Improved product quality: The PILS-330 creates a strong, sift-proof seal that helps to protect your products from contamination and leakage.

- Versatility: The PILS-330 can be used to seal a variety of bag sizes and styles, including Cap-Sac style multi-wall paper bags.

- Easy to use: The PILS-330 is equipped with a number of user-friendly features, such as a digital temperature display and a keypad for variable speed control.

- Safe to use: The PILS-330 is equipped with dual emergency e-stop buttons for added safety.

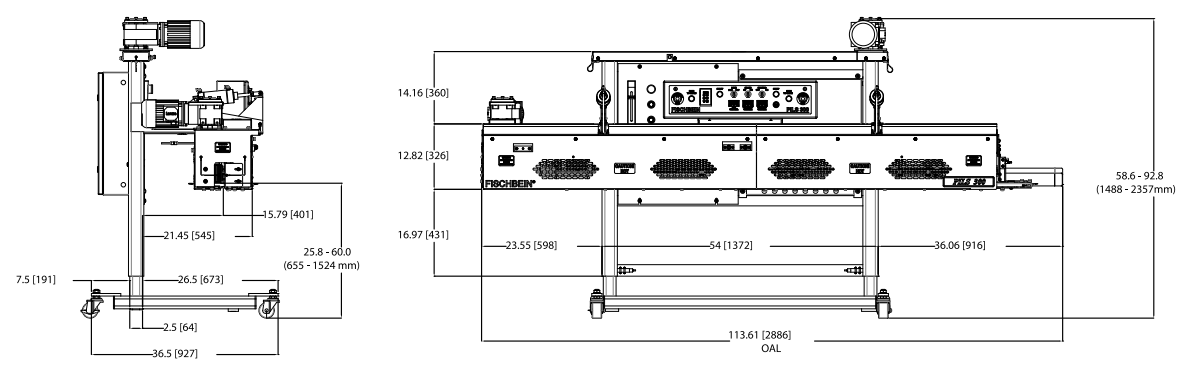

Dimensional drawings of the Fischbein PILS-330

Startup, Preventative Maintenance, and In-Plant Services:

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new Fischbein PILS-330 equipment. This includes verifying that the equipment is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for all of your Fischbein equipment. To ensure your packaging equipment operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services:

Inpak Systems offers in-plant repair of your Fischbein PILS-330 equipment. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your equipment is restored to original factory operating specifications. Dispatched from our WI location, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

The blog post above is geared toward the Closing end of the packaging process. Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We continue to work with a variety of top-notch companies for 35+ years and counting, providing simple and sophisticated packaging solutions for small, medium & large businesses.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and parts & services are just a few steps away.

Make a positive impact and contact Inpak Systems.