Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

In this blog post, we’re reviewing a Filling option in the form of the Express Scale ESP JM-FF-ED Bagging Gross Weigher.

Express Scale ESP JM-FF-ED Bagging Gross Weigher

The ESP JM-FF-ED Bagging Gross Weigher is fully electronic and digitally controlled. The JM-FF-ED Electronic Gross Weigher* simultaneously weighs and fills open-mouth bags weighing between 20 and 110 pounds at speeds up to eight bags per minute, depending on your operational parameters. The dual-position gravity gate allows for bulk or dribble feed and provides accuracies of +/- 4 ounces, based on product flow and the consistency of bulk density.

Wraparound bag clamps are sized to your particular bag requirements. Air-operated center-grip bag spout facilitates dust control with a flexible connection to the main housing. GSE 465 controller with IP-66 stainless steel enclosure is rated NEMA 4X and features Final Target Weight, Slow Fill, Free Fall, Fill Delay, Clamp Delay, and Pound/Kilogram controls.

*Gross weigh = product is weighed as it is put in the container

Key Features of the ESP JM-FF-ED:

- Fully electronic and digitally controlled: Provides accurate and consistent weighing and filling

- Simultaneous weighing and filling: Fills open-mouth bags while weighing them, improving efficiency

- Handles bags from 20 to 110 pounds: Accommodates a wide range of product weights

- Speeds of up to 8 bags per minute: Increases production output

- Dual position gravity gate: Allows for bulk or dribble feed, depending on the product

- Accurate to +/- 4 ounces: Minimizes product giveaway and ensures precise filling

- Wraparound bag clamps: Securely hold bags of various sizes

- Air-operated center-grip bag spout: Facilitates dust control and connects easily to the main housing

- Shipped in separate components: Makes installation and maintenance easier

- Factory calibrated: Ready to use out of the box

Benefits of the ESP JM-FF-ED:

- Increased accuracy and consistency: Reduces product giveaway and improves quality control

- Improved efficiency: Fills bags faster, leading to higher production volumes

- Versatility: Handles a wide range of bag sizes and weights

- Reduced labor costs: Requires less manual handling of bags

- Improved dust control: Minimizes dust generation during filling

- Easy installation and maintenance: Makes it simple to set up and maintain the scale

- Reduced downtime: Less likely to experience breakdowns or calibration issues

Quick Comparison of JM-FF-ED and GB-32 from Express Scale models

Both the JM-FF-ED and the GB-32 from Express Scale are gross weigh baggers, meaning they weigh the bag and contents together. However, they differ in their level of automation and operation. Here’s a comparison to help you choose the best one for your needs:

Operation:

- JM-FF-ED: Electronic. The scale automatically weighs the product and stops filling when the desired weight is reached

- GB-32: Manual. The operator pulls a lever to open the gate and fill the bag. Weight is controlled by adjusting the filling time

Speed:

- JM-FF-ED: Up to 8 bags per minute, depending on bag weight and product flow

- GB-32: 4-5 bags per minute

Accuracy:

- JM-FF-ED: +/- 4 ounces, based on product flow and consistency

- GB-32: +/- 4 ounces

Other features:

- JM-FF-ED: More features like dual position gravity gate for bulk or dribble feed, adjustable flow control, dust control connection, and programmable timers

- GB-32: Simple and durable, requires minimal maintenance. Can be customized with different spout sizes and shapes

Cost:

- JM-FF-ED: More expensive due to its electronic components and features

- GB-32: Less expensive

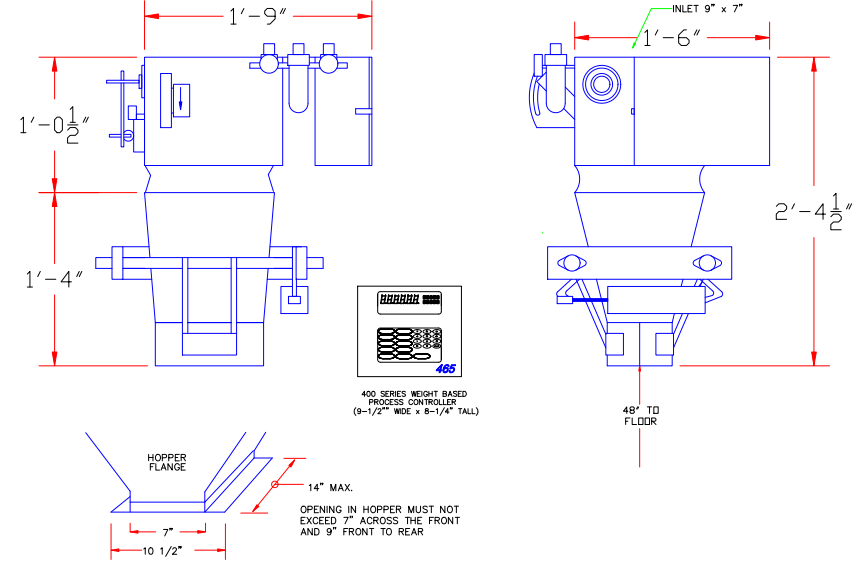

Approximate Dimensional Drawings

Startup, Preventative Maintenance, and In-Plant Services

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new JEM Wildcat GWD. This includes verifying the JEM Wildcat GWD is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your JEM Wildcat GWD. To ensure your JEM Wildcat GWD operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services

Inpak Systems offers in-plant repair of your JEM Wildcat GWD. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your JEM Wildcat GWD is restored to original factory operating specifications. Dispatched from our WI location, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling Your Packaging Needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

The blog post above is geared toward the Filling end of the packaging process. Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We continue to work with a variety of top-notch companies for 35+ years and counting, providing simple and sophisticated packaging solutions for small, medium & large businesses.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and Parts & Services are just a few steps away.

Make a positive impact and contact Inpak Systems.