Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

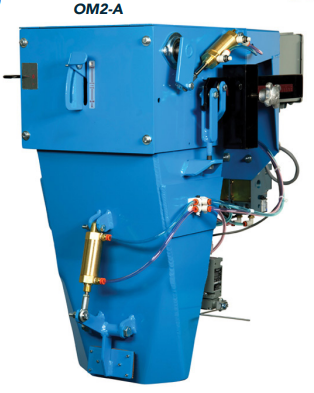

In this blog post, we’re reviewing a Filling option in the form of the Taylor OM2 (and OM2-A) Gross Weigh Open Mouth Bagger.

Taylor OM2 (and OM2-A) Gross Weigh Open Mouth Bagger

The Taylor OM2 (and OM2-A) is a gravity-fed, gross weigh*, open-mouth bag scale. The OM2 can fill 15 lb. to 125 lb. bags with free-flowing materials such as grain, granules, feed, seed, and corn at rates up to 12 bags per minute.

The OM2 is available with various size spouts in either a manual (OM2) or an automated (OM2-A) version. With the OM2 manual mechanical version: the operator places the bag on the spout, clamps the bag, and activates the fill control. When the bag reaches the desired weight, the scale shuts off and the operator can remove the bag.

The OM2-A automated version uses a pneumatic bag clamp with auto bag release. The operator places the bag on the spout and activates the fill control. The bag is automatically clamped on the spout, is filled, and then dropped off. The Model OM2 scale utilizes Taylor’s patented beam scale is self-dampening and the weight pointer and calibration adjustment are located directly on the beam.

*Gross weigher = product is weighed as it is put in the container

Photos of Taylor OM2 and OM2-A Gross Weigh Open Mouth Baggers

Key Features of the Taylor OM2 (and OM2-A):

- Simple and robust design: The OM2 features a straightforward mechanical operation with minimal moving parts, making it easy to maintain and less prone to breakdowns

- Adjustable flow gate: This allows you to control the rate of material flow into the bag, ensuring accurate and consistent filling

- Concentric bag clamp: The OM2’s manual clamp securely holds the bag in place during filling

- Accuracy: The OM2’s self-dampening beam scale provides good accuracy for most applications

- Wide weight range: The OM2 can handle bags ranging from 25 to 150 pounds, making it versatile for various bagging needs

- OM2-A v OM2: The OM2-A has all the features of the OM2, plus:

- Pneumatic bag clamps with automatic bag release: These clamps hold the bag securely during filling and automatically release once the desired weight is reached, improving efficiency and ease of use

- Faster filling: The automatic release of the OM2-A bag clamps allows for faster filling compared to the manual clamps of the OM2

- Slightly higher cost: The additional features of the OM2-A come at a slightly higher price point than the OM2

- Materials Typically Handled are dry, granular free-flowing products such as:

- Wheat

- Feed Mixes

- Granular Fertilizer

- Cracked Corn

- Deer Corn Mixes

Benefits of the Taylor OM2 (and OM2-A):

- Mechanical operation: Requires no electricity* or compressed air, making them ideal for use in remote locations or where power is limited

- *Caveat: The OM2-A requires electricity for the automation of the pneumatic bag clamps

- Easy to use and maintain: Their simplicity makes them user-friendly, even for operators with limited experience

- Durable construction: Built with high-quality materials for long-lasting performance

- Versatile: Can handle a wide range of bag sizes and weights

- Affordable: A cost-effective option compared to many other open-mouth baggers

Quick Comparison of models OM2 (and OM2-A) and TE100 from Taylor

The Taylor OM2 (and OM2-A) and TE100 are open-mouth baggers designed for filling bags with free-flowing granular materials like seeds, grains, sand, and pellets. However, they cater to different needs and budgets, making it essential to understand their key differences before making a choice. Here’s a comparison to help you choose the best one for your needs:

Operation:

- OM2 (and OM2-A): Completely mechanical, requiring no electricity* or compressed air, but more manual operation

- *Caveat: The OM2-A requires electricity for the automation of the pneumatic bag clamps

- TE100: Semi-automated with an electronic scale and self-correcting features, requires power and compressed air

Filling Speed:

- OM2 (and OM2-A): Up to 12 bags per minute

- TE100: Up to 14 bags per minute

Accuracy:

- OM2 (and OM2-A): Good accuracy with a self-dampening beam scale, but not as precise as the TE100

- TE100: Higher accuracy with a digital electronic scale and programmable over/under weight limits

Weight Range:

- OM2 (and OM2-A): 25 to 150 pounds

- TE100: 20 to 125 pounds

Other Features:

- OM2 (and OM2-A): Adjustable flow gate, concentric bag clamp (OM2) or pneumatic bag clamps with automatic release (OM2-A)

- TE100: Bulk and dribble flow gate, NEMA 12 enclosure, painted carbon steel frame

Cost:

- OM2 (and OM2-A): Less expensive due to its simpler design

- TE100: More expensive due to its electronic components and features

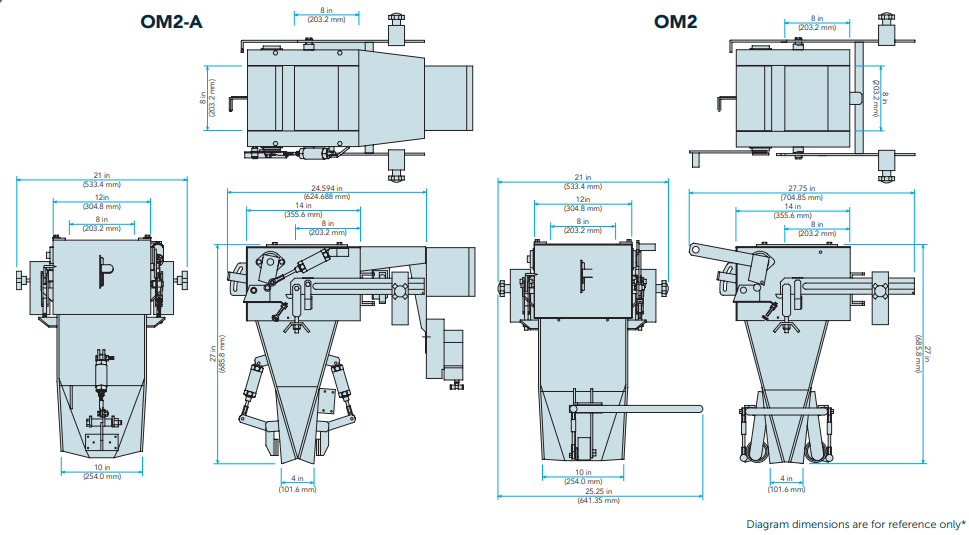

Approximate Dimensional Drawings of the Taylor OM2 (and OM2-A)

Startup, Preventative Maintenance, and In-Plant Services

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new Taylor OM2 (and OM2-A). This includes verifying the Taylor OM2 is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Taylor OM2. To ensure your Taylor OM2 operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services:

Inpak Systems offers in-plant repair of your Taylor OM2. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Taylor OM2 is restored to original factory operating specifications. Dispatched from our WI location, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and Parts & Services are just a few steps away.

Make a positive impact and contact Inpak Systems.