INPAK SYSTEMS offers a variety of pinch bag sealers that are used to close multi-wall paper and woven poly bags.

Pinch, Double Roll Over, PILS (pinch inner liner sealer) and PTP (poly through paper) sealers are available in semi and fully automated models. Because of the typical size of the bags (20 – 110 lbs.), pinch sealers generally have a bag support conveyor. Options include: coders, bag top trimmers and support conveyors.

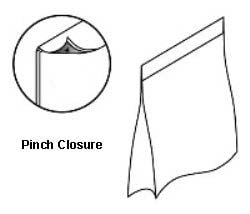

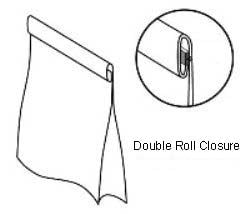

Pinch top bags have hot melt glue which is pre-applied to their tops. As the bag is pulled through the pinch sealer, hot air melts the glue. The bag top is then folded over and squeezed together sealing the bag closed. Some bags have a separate PE inner liner (PILS) that is heat-sealed prior to sealing the paper bag top.

Bag Pinch Sealers are ideal for a variety of products including food, dry pet food, and more. Learn more about our industries served here.

Videos of pinch bag sealers in action.

Contact Us to receive more information about our product lines.

For more information on a specific pinch bag closer, select one of the products below. If you need help choosing a bag pinch sealer for your needs, contact us.

Pinch Bag Sealer FAQs

Multi-wall paper, woven poly and poly lined paper bags.

Pinch, DRC (double roll over), PILS (pinch inner liner sealer) and PTP (poly-through-paper).

Typically, dry solids and powders.

2 lb. to 120 lb. bags depending on the model. We recommend a bag supporting conveyor for all pinch sealers.

12″ to 69” long, up to 56″ wide depending on the model.

Up to 110 ft/min. depending on the model.

We offer pinch bag sealers from Fischbein/nVenia and American Newlong.

Pinch bag sealers are normally integrated into automated bagging lines.

Transfer conveyors, air scrubber, L>R feed, coder, NEMA 4 enclosure, motorized height adjustment, top trim, jam detector, & reverse fold.

220/440 VAC, 3 Ph, 60c Hz

Yes, requirements vary by model.

Mild steel, stainless steel, & wash-down models are available

We recommend testing all bags to ensure proper performance.

Yes, the startup service includes operation verification, operator training, and maintenance training. To schedule a startup service, contact us at 608-221-8180 ext. 3 or [email protected].

Yes, we offer in-plant repair service To schedule a repair service, contact us at 608-221-8180 ext. 3 or [email protected].

We stock most parts. Other parts are drop shipped from the manufacturer. To order parts, contact us at 608-221-8180 ext. 3 or [email protected].

Yes, quarterly, and annual preventive maintenance contracts are available. For more information, contact us at 608-221-8180 ext. 3 or [email protected].

The warranty period is established by the manufacturer and is typically 12 mos.