Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

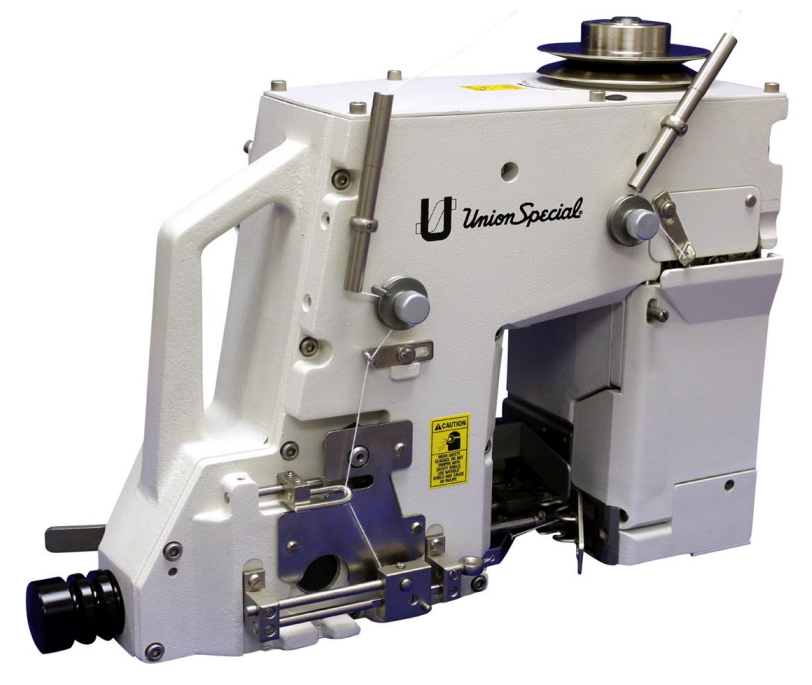

In this blog post, we’re reviewing a Closing option in the form of the Union Special (US) BC200 Sewing System.

Union Special BC200 Series Sewing System

The US BC200 Series Sewing System is a heavy-duty bag-closing machine for filled bags made from burlap, jute, cotton, plastic, paper, poly and poly-laminated bags. It is also suitable for bituminized or foil-laminated materials.

The US BC200 is the fastest bag closer on the market, capable of sewing at speeds of up to 85 feet per minute (75 feet per minute for tape closure). It is manufactured in the United States by Union Special Corporation, which has been in business since 1881.

Photo of Union Special BC200

Key features of the US BC200:

- Sews at speeds of up to 85 feet per minute

- Totally enclosed, which protects the machine’s motor from dust and dirt

- Self-lubricating oil system keeps the machine running smoothly

- Needle thread chain cutter cuts the needle thread automatically after each bag is closed

- Greifer thread chain cutter cuts the greifer thread automatically after each bag is closed

- Automatic bottom feed, feeds the bottom of the bag automatically

- Automatic top feed, feeds the top of the bag automatically

- Automatic stitch tension ensures consistent stitch quality

- Automatic bag size adjustment, adjusts the machine to different bag sizes automatically

- Easy to operate with simple controls

- Durable and built to last with high-quality materials

Benefits of using the US BC200

- Speed: With mechanisms rated for 3100 rpm and a rotary-shaft design, the BC200 can reach speeds of up to 85 feet per minute (depending on the application), making it the fastest bag closer on the market

- Fast & accurate stitching: The US BC200 produces a dual thread, double lock, type 401 stitch at rates of up to 2750 stitches per minute. This allows for faster bag closing and increased production efficiency.

- Enclosed for protection: The BC200 is the only bag closer on the market that is completely enclosed. This protects the machine’s motor from dust, dirt, and other contaminants, which can extend its lifespan and prevent breakdowns.

- Self-oiling advantage: The BC200 machine has a self-oiling lubrication system that ensures all parts are properly lubricated, reducing wear and tear and further enhancing its reliability

- Noise reduction: The rotary-shaft design of the BC200 results in low vibration, which reduces noise and operator fatigue and contributes to longer machine life

- Tape saving: The BC200 features a guillotine cutter for taping operations, which can save up to 60% on tape costs

- Adaptable stitching: It can sew with stitch lengths ranging from 2 to 4 stitches per inch, making it adaptable to various bag materials and closure requirements

- Ease of use: The BC200 is designed for user-friendly operation with simple controls and features for ease of operation

- Lower maintenance & costs: The BC200’s enclosed design and self-lubricating system contribute to reduced maintenance requirements and associated costs, as well as reduced downtime as it requires less maintenance than other machines

- Consistency: The BC200 sews bags with consistent stitch quality

Quick Comparison of US BC200 v US 80800 models

Speed comparison:

- BC200: Up to 2750 stitches per minute (SPM)

- 80800: Up to 2000 SPM

Start/stop comparison:

- BC200: Photo eye (standard) or feeler-controlled proximity switch

- 80800: Footswitch

Thread chain cutter comparison:

- BC200: Automatic, electro-pneumatically operated jump-out scissors (standard) or continuously driven nibbler knives

- 80800: Manual

Features comparison:

- BC200: Self-oiling lubrication system, low noise and vibration, shell design casting, variable pitch pulley/handwheel, compatible with existing installations, simplified maintenance, less operator fatigue and longer part life, easy adjustments and maintenance, easily set a loose or tight stitch as needed, quick speed adjustments

- 80800: Standard bag closer with no electrical components, suitable for ex-proof locations, optional single-thread chainstitch

Applications comparison:

- BC200: High production bag closing for plain and fold-over closures, sew-thru tape closures

- 80800: Closing of hazardous materials, low-to-medium production

Startup, Preventative Maintenance, and In-Plant Services

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new Union Special BC200 equipment. This includes verifying that the equipment is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for all of your Union Special equipment. To ensure your packaging equipment operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services:

Inpak Systems offers in-plant repair of your Filling, Conveying, or Closing equipment. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your US BC200 equipment is restored to original factory operating specifications. Dispatched from our WI location, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

The blog post above is geared toward the Closing end of the packaging process. Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We continue to work with a variety of top-notch companies for 35+ years and counting, providing simple and sophisticated packaging solutions for small, medium & large businesses.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and parts & services are just a few steps away.

Make a positive impact and contact Inpak Systems.