Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

In this blog post, we’re reviewing a Filling option in the form of the Chantland 4219 and 4219L Vibraweigh Open-Mouth Vibratory Gross Weigh Bagger.

Chantland models 4219 and 4219L Vibraweigh Open-Mouth Gross Weigh Bagger

The Chantland 4219 and Chantland 4219L Vibraweigh is a gravity-fed, gross weigh*, vibratory, open-mouth bag scale. The 4219 can fill 1 lb. to 25 lb. bags and the 4219L can fill 20 lb. to 110 lb. bags.

The 4219 and 4219L Vibraweigh Fillers (Standard, Table Top, and Large Models) are designed to weigh and fill open-mouth bags, boxes, pails, and drums with dense dry pelleted, granular, powdered, or irregularly shaped products such as seeds, feed pellets, gravels, and similar materials.

Product is placed into the filler’s surge bin. As the vibratory feeder runs, the feeder tray meters product into the container. When the appropriate amount of weight is registered in the container, the feeder stops and the operator can signal to discharge the container. Bulk-Dribble feed can be provided with load cell weigh.

*Gross weigher = product is weighed as it is put in the container

Photos of Chantland 4219 and 4219L

Key Features of the Chantland 4219 & 4219L:

- Scale beam gross weigh (with an option for net weigh)

- 4219: Ideal for filling 1 to 25 lb. smaller bags or containers

- 4219L: Handles larger loads, filling 20 to 110 lb. larger bags or containers

- High accuracy: It uses a load cell to ensure consistent filling weights within ±0.1% of the target weight, reducing material waste and improving product quality

- Fast filling speeds: The vibratory feeder quickly moves material into the bag or container, with the model 4219 filling up to 25 bags per minute, depending on material and bag size. This translates to increased productivity and efficiency. The fill rates for the model 4219L are up to four (4) 50 lb. bags per minute.

- Easy to operate: The simple control panel with a digital display allows for intuitive operation, even for untrained personnel. This minimizes training costs and downtime

- Durable construction: Made of heavy-duty stainless steel and other robust materials, the Chantland 4219 and 4219L withstand demanding environments and ensure long-lasting performance

- Versatile: It can handle a wide range of dry, free-flowing materials, from powders and pellets to granules and odd-shaped pieces, making it suitable for various applications

- Adjustable settings: Operators can fine-tune the vibration frequency and amplitude to optimize filling for different materials and bag sizes, ensuring consistent and accurate filling across batches

- Foot pedal control: The optional foot pedal allows for hands-free filling, improving operator comfort and potentially increasing filling speed

- Spout: 5 1/2” x 7” oval spout

- Power: NEMA 12 electrical system

- Frame: Mild steel construction

- Compact size: Its small footprint makes it ideal for operations with limited space constraints

Additional options for the models 4219 and 4219L:

- Net weighing: An optional net weighing bucket can further increase accuracy and speed, especially for lightweight materials

- Dust collection hood: Protects the operator and surrounding environment from dust during filling

- Flow control gate: Ensures precise material cutoff for clean and consistent fills

- Special paint finishes and electrical packages: Can be customized to meet specific requirements (e.g., food-grade) and environmental conditions (e.g., anti-corrosive)

Benefits of the Chantland models 4219 and 4219L:

- Increased productivity: The fast filling speeds and large capacity help you fill more bags or containers per hour, boosting your production output

- Reduced material waste: Accurate weighing minimizes overfilling and underfilling, saving you money on material costs

- Improved worker safety: Hands-free operation with the optional foot pedal can reduce worker fatigue and minimize the risk of injuries

- Lower operating costs: Durable construction and minimal maintenance requirements contribute to lower long-term costs

- Flexibility: The versatility of the scale makes it suitable for a wide range of applications and materials

Quick Comparison of models 4219 and 4219L from Chantland

The Chantland 4219 and Chantland 4219L are vibratory open-mouth baggers designed for filling bags with free-flowing granular materials like seeds, grains, sand, and pellets. However, they cater to different needs and budgets, making it essential to understand their key differences before making a choice. Here’s a comparison to help you choose the best one for your needs:

Operation:

- 4219 for smaller fills, limited space, and a tighter budget

- 4219L for large fills, high-volume production, and industrial applications

Weight Range:

- 4219: Ideal for filling 1 to 25 lb. smaller bags or containers

- 4219L: Handles larger loads, filling 20 to 110 lb. larger bags or containers

Filling Speed:

- 4219: Up to six (6) 25 lb. bags per minute / Up to 25 bags per minute, depending on material and bag size

- 4219L: Up to four (4) 50 lb. bags per minute

Accuracy:

- 4219: +/- 4 to 6 ounces from target weight (+/- 2 to 4 ounces with load cells)

- 4219L: +/- 4 to 6 ounces from target weight (+/- 2 to 4 ounces with load cells)

Note:

- Accuracy: Can vary depending on the material being filled with fine powders or irregularly shaped materials being more challenging to weigh accurately than larger, uniform granules

- Filling speed: While both models offer fast filling speeds, slower speeds can generally lead to higher accuracy

- Calibration: Regular calibration of the scale is essential for maintaining optimal accuracy

Cost:

- 4219: Less expensive due to its lower weight capacities

- 4219L: More expensive due to its higher weight capacities

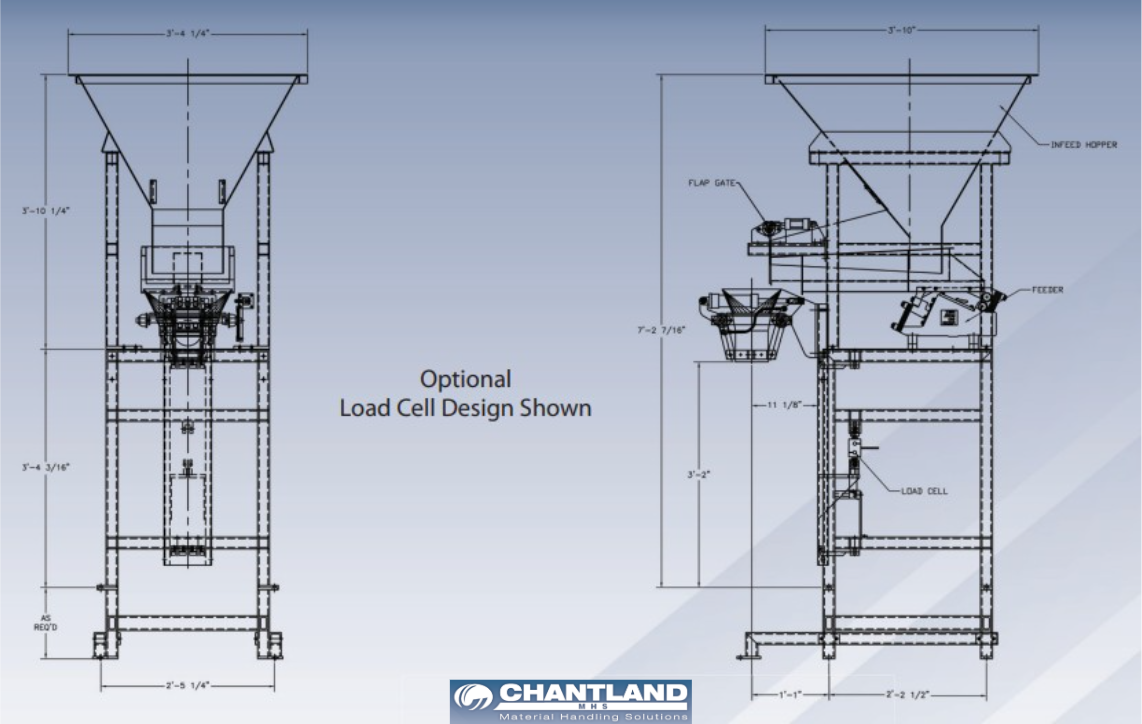

Approximate Dimensional Drawings of the Chantland 4219 and 4219L

Startup, Preventative Maintenance, and In-Plant Services

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new Chantland 4219 or 4219L. This includes verifying the Chantland 4219 or 4219L is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Chantland 4219 or 4219L. To ensure your Chantland open-mouth bagger operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services:

Inpak Systems offers in-plant repair of your Chantland 4219 or 4219L. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Chantland is restored to original factory operating specifications. Dispatched from our WI location, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and Parts & Services are just a few steps away.

Make a positive impact and contact Inpak Systems.