Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

In this blog post, we’re reviewing a Filling option in the form of the Hamer Model HGB Gross Weigh Mechanical Bagging Scale.

Hamer Model HGB Gross Weigh Bagging Scale

The Hamer Model HGB Gross Weigh Mechanical Bagging Scale. The Model HGB uses a mechanical counterbalance weight set and requires no electrical or compressed air. It is an ideal solution for manual bagging of free‐flowing granular products, such as fertilizers, sugar, salt, plastic pellets, seeds, or animal feed. The Model HGB is available in mild steel or stainless steel construction with a choice of two (2) spout sizes.

Photo of Hamer HGB Gross Weigh Mechanical Bagging Scale

Key features of the Hamer HGB:

- Mechanical operation: No electricity or compressed air is required, making it a low-maintenance and budget-friendly choice

- Gross weigh system: Weighs the entire bag with product, ideal for operations where tare weight variations are minimal

- Easy weight adjustment: Simple to set and adjust desired fill weights using a counterbalance weight system

- Wide weight range: Handles bags from 10 lbs. to 150 lbs. (5kg to 70kg), offering versatility for various products

- Adjustable flow control gate: Regulate the product flow rate for precise filling

- Durable construction: Available in mild steel or stainless steel options for longevity and suitability for different environments

- Choice of spout sizes: Large (16″ minimum bag width) or small (12.5″ minimum bag width) to accommodate various bag sizes

- 6-8 bags per minute (BPM) fill rate: Efficient for manual bagging operations, but dependent on material flow characteristics

- Mechanical indicator for weight variance: Alerts the operator to bags exceeding or falling below the target weight

Benefits of the Hamer HBG:

- Cost-effective: Affordable purchase and operation compared to electronic bagging scales

- Simple to use: Easy to install, operate, and maintain, ideal for low-tech environments

- Reliable: No complex electronics to malfunction, making it a dependable choice for long-term use

- Versatile: Suitable for various free-flowing granular products like fertilizers, sugar, salt, pellets, seeds, and animal feed

- Portable: Relatively lightweight and compact for easy movement within the workspace

- Safe: No electrical hazards or compressed air risks, creating a safer working environment

Quick Comparison of Hamer Model HGB and Hamer 100GW

Choosing between the Hamer Model HGB and Hamer 100GW depends on your specific needs and priorities. Here’s a quick comparison to help you decide:

Operation:

- HGB: Manual. The operator pulls a lever to open the gate and fill the bag. Weight is controlled by adjusting the filling time.

- 100GW: Electronic. The scale automatically weighs the product and stops filling when the desired weight is reached.

Speed:

- HGB: Varies depending on the operator

- 100GW: Up to 20 bags per minute

Accuracy:

- HGB: +/- 4 ounces

- 100GW: +/- 2 ounces

Versatility:

- HGB: Handles a wide range of bag sizes and weights

- 100GW: Limited to small/medium bags

Dust Control:

- HGB: Minimal

- 100GW: Optional dust collection system

Ease of Use:

- HGB: Requires training and manual operation

- 100GW: Simple push-button operation

Maintenance:

- HGB: Regular calibration and service required

- 100GW: Minimal maintenance

Cost comparison:

- HGB: More affordable

- 100GW: More expensive

Choosing the right Hamer scale for your needs:

- HGB is ideal for: Low-volume operations; tight budgets; manual bag handling; simple weighing needs

- 100GW is ideal for: High-volume operations; precise filling requirements; dust control concerns; ease of use; minimal maintenance

- Material being weighed: Both scales can handle dry goods, but the 100GW may be better suited for fine or dusty materials

- Desired level of automation: If you need a quick and efficient filling process, the 100GW is the better choice

- Budget: The HGB is a more affordable option, but the 100GW will save you time and labor in the long run

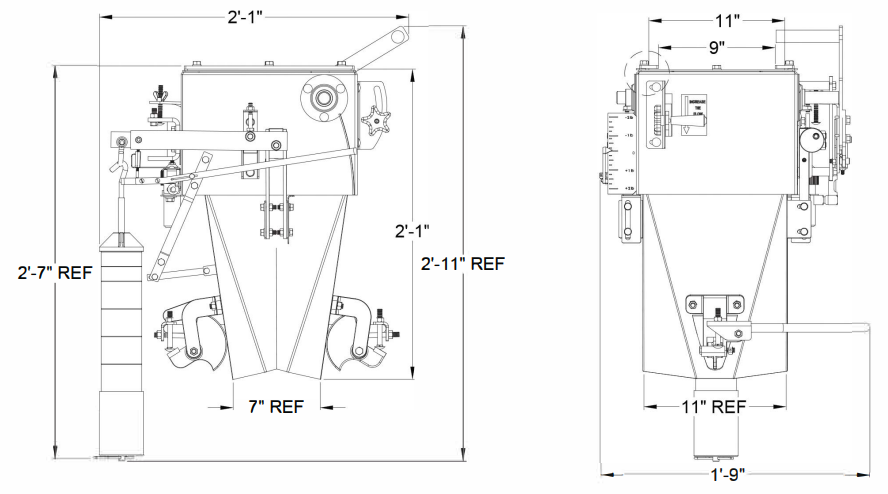

Dimensional Drawings of Hamer HGB mechanical bagging scale

Startup, Preventative Maintenance, and In-Plant Services

Inpak is unique in that our Field Service Technicians can perform Startup, Preventative Maintenance, and In-Plant Services on all of our equipment. We’re ready and able to assist you to get and keep your packaging equipment up & running.

Startup Services:

Inpak Systems offers a startup service on your new Model HGB. This includes verifying the Model HGB is operating properly to factory specifications. The startup service includes operation verification, operator training, and maintenance training.

Preventative Maintenance Services:

To prevent downtime and costly emergency repairs, preventive maintenance (PM) services are available for your Model HGB. To ensure your Model HGB operates at maximum efficiency, PMs can be arranged to fit your production schedule.

In-Plant Repair Services

Inpak Systems offers in-plant repair of your Model HGB. Our experienced, factory-trained, and certified technicians use genuine OEM parts to ensure your Model HGB is restored to original factory operating specifications. Dispatched from either our WI or OH locations, we offer national coverage and we ensure a quick response throughout the Midwest.

Contact Inpak for a Field Service Estimate

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and Parts & Services are just a few steps away.

Make a positive impact and contact Inpak Systems.