Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services

Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We work with a variety of top-notch industrial packaging companies. Inpak offers well-made, durable, and competitively priced machinery, all of which perform consistently well for customers and packaging lines of all sizes. We’ve been providing simple & sophisticated packaging solutions for small, medium & large businesses for 35+ years.

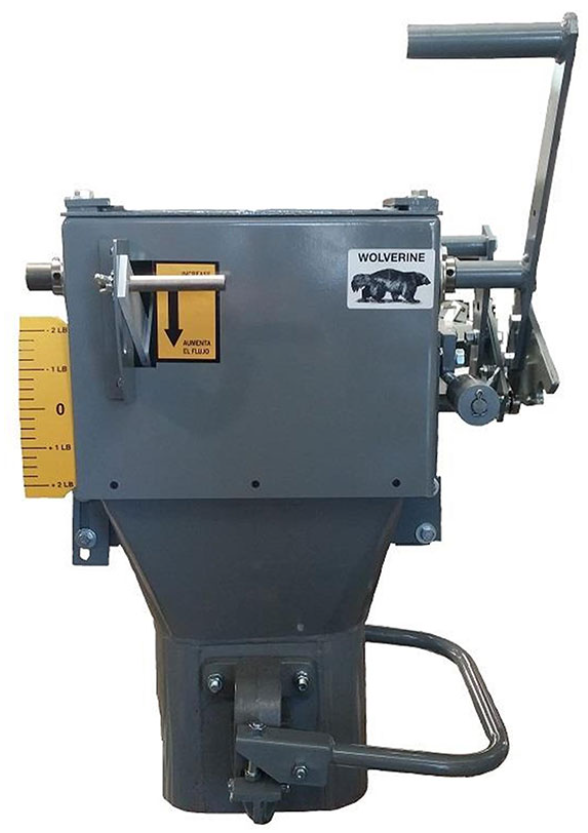

In this blog post, we’re reviewing a Filling option in the form of the JEM International Wolverine GWM Bagging Scale.

JEM Wolverine GWM Bagging Scale

The JEM Wolverine GWM Bagging Scale is a Gross Weigh Mechanical scale for open-mouth bags. It is designed to weigh free-flowing materials such as corn, soybeans, salt, pellets, prilled fertilizers, and sugar. It offers an economical approach to filling bags from 10 lbs. to 110 lbs. (5 kg – 50kg) with typical production speeds of 5-6 (50#) bags per minute with an accuracy of ± 4 ounces (100 grams).

The GWM scales can be supplied with a variety of spout sizes to accommodate your specific bag dimensions. Flex-Belt and Auger feeders are available to handle products that are not free-flowing in nature. The scales are available in mild 10 gauge steel (GWM) or can be supplied with stainless steel product contact surfaces (GWM-S) or all stainless steel construction (GWM-SS) for corrosive products or for food-grade products (GWM-FG) such as salt, fertilizer, and various food products.

Photo of JEM Wolverine GWM Bagging Scale

Key features of the JEM Wolverine GWM include:

- High accuracy: ±4 oz (100 gram) accuracy on all free-flowing materials

- Fast filling speeds: Up to 5-6 bags per minute

- Wide range of bag sizes: Accommodates bags from 20 to 110 lbs. (10 kg – 50kg)

- Design: Dust-tight design

- Flexible spout sizes: A variety of spout sizes are available to accommodate different bag dimensions

- Durable construction: Available in mild 10 gauge steel or with stainless steel product contact surfaces

- Easy operation: Simple and intuitive controls

- Low maintenance: Requires minimal maintenance

- Variety of options: Available with Flex-Belt and Auger feeders for non-free-flowing materials, and in all-stainless steel construction for corrosive or food-grade products

Benefits of the JEM Wolverine GWM include:

- Cost-effective: Provides an economical solution for bag filling

- Increased productivity: Fills bags quickly and efficiently, boosting production output

- Improved accuracy: Ensures consistent bag weights

- Reduced waste: Minimizes product giveaway with accurate filling

- Versatile: Handles a wide range of bag sizes and materials

- Durable: Built to last in demanding environments

- Easy to use: Requires minimal training for operators

- Low maintenance: Saves time and money on upkeep

Applications:

The JEM Wolverine GWM is a versatile and affordable bagging scale that is ideal for a variety of industries, including:

- Agriculture

- Chemical

- Feed & Grain

- Food

- Industrial

- Pet Food

- Seed

Quick Comparison of JEM Wolverine GWM v JEM Wildcat GWD models

Type comparison:

- JEM Wolverine GWM: Mechanical

- JEM Wildcat GWD: Digital

Accuracy comparison:

- JEM Wolverine GWM: ±4 ounces (100 grams)

- JEM Wildcat GWD: ±2 ounces (50 grams)

Speed comparison:

- JEM Wolverine GWM: 5-6 bags per minute

- JEM Wildcat GWD: 8 bags per minute

Capabilities comparison:

- JEM Wolverine GWM: Simple, durable, economical

- JEM Wildcat GWD: Faster, more accurate, programmable, NEMA 4X-IP65 rated

Applications comparison:

- JEM Wolverine GWM: Lower-volume production, budget-conscious operations

- JEM Wildcat GWD: Higher-volume production, accuracy for critical applications

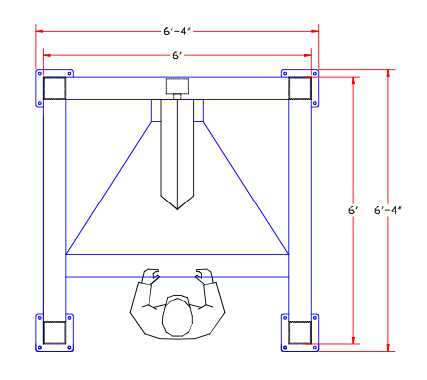

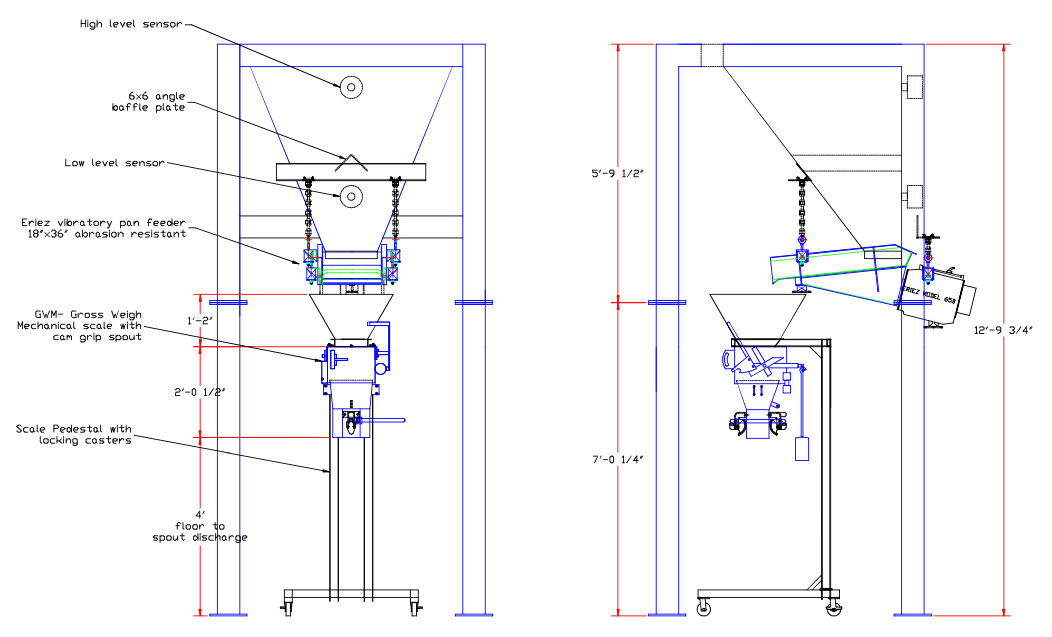

Dimensional drawings of the JEM Wolverine GWM

Filling your packaging needs

How can Inpak Systems help you with your industrial packaging needs? Contact us at 608-221-8180, [email protected], and/or fill out the Packaging Needs Worksheet here. Find out more on our Inpak YouTube channel and subscribe to stay updated as we continue to expand our product lines.

The blog post above is geared toward the Filling end of the packaging process. Inpak Systems offers end-to-end industrial packaging solutions, consumables, parts & services since 1986. We continue to work with a variety of top-notch companies for 35+ years and counting, providing simple and sophisticated packaging solutions for small, medium & large businesses.

Whether it’s Filling -> Closing -> Conveying -> Finishing -> Consumables -> Parts & Services…we likely have what you need to take your business to the next level. Inpak Systems’ packaging solutions and parts & services are just a few steps away.

Make a positive impact and contact Inpak Systems.